Weatherboards are often made from pine and are pre-primed, meaning that a single coat of primer has been put to both sides to preserve them from the elements. Their edges are typically squared off or have a bullnose shape. Some houses also have feature façade in select places, and these weatherboards get a shape that includes a "V-notch" added to them for decorative purposes.

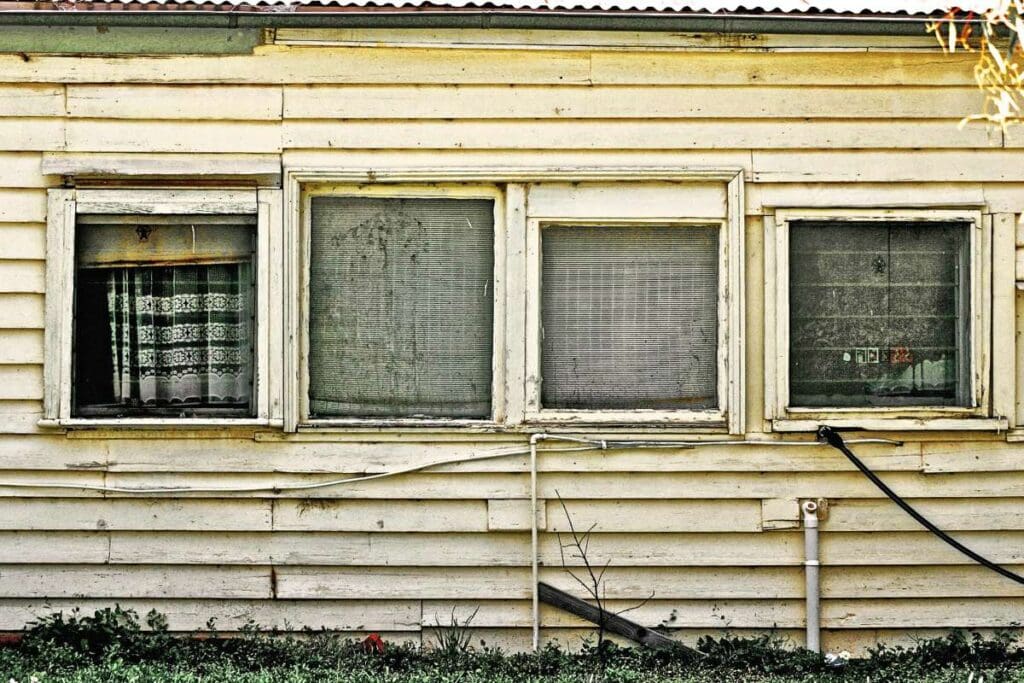

My own opinion is also that weatherboards convey an air of refinement and may be found in nearly every era of architecture in Australia. They are simple to replace in the occasion that they become broken or if the lapse of time has forced their strength to weaken.

The most recent improvement in weatherboard technology is the treated wood variety. The weatherboards are treated with Light Organic Solvent Artificial ingredients (LOSP) to protect them from rot, termites, and other wood-eating organisms for the long haul.

These planks have been given two coats of external primer that is both water- and acrylic-based. You can skip applying a guide or undercoat altogether. Weatherboards can be fabricated from cement sheet and come in a range of profiles to suit both classic and modern home designs. Looking for the best weatherboard repairs company? Look no further! Hitch Property Constructions has you covered.

Installation Of New Weatherboards

Weatherboards are a type of exterior siding that are long and flat. Homes can be made more secure and attractive with the use of weatherboards. They go by a variety of other names, including clapboards, lap planks, and bevel siding. The weatherboards on a building are overlapped during installation to form a strong defence against the elements. Weatherboards were first made out of pine, spruce, and oak.

Items Required:

- Clawhammer with a Lever

- A Saw That Can Cut in Both Directions

- Straight-cut pliers

- Crosscut saw

- Handsaw (optional) (optional).

- The use of silicone caulk.

- Those nails belong to Shank.

- Paint.\Brush.

- Modern weatherboards can include wood, composites, or another material. Even though synthetic weatherboards tend to be more durable than their natural counterparts, they are nonetheless susceptible to a variety of damages. Weatherboards are easily replaced if they become damaged.

- Get yourself acquainted with the insulation boards you'll be dealing with, including the board you'll be replacing, the board above it, and the board below it. You can refer to the board you're replacing as "board A," as it's the one above it. To be specific, you are swapping out Board B. The board you need to modify is C, which is the board beneath the one you're now working on.

- Try jamming the end of a crowbar between planks A and B. Two nails, one at the top and a second at the bottom, are used at each stud throughout the length to secure the weatherboards. Lift board A by prying up its underside, working your way from one nail head to the next. At the very least, the spying motion should loosen and raise board A along with the nail head by 1⁄2 an inch.

- Place the crowbar's pointer between boards B and C and tap. Using a pry bar, pry up as high as you can on board B and also the nails.

- Boards A and B must be tapped down with a meat cleaver so that the nail heads are visible. To remove the nails, strike them with a claw hammer.

- If there are any nails that you just can't seem to get rid of no matter how much you pound on them, you can use a reciprocating saw to lop off the damaged or stubborn heads. To finish off the nail, use diagonal pliers to remove the fragment that remains.

- Hold board B, the one you're swapping out, firmly in both hands. To remove it from the building, wiggle it upward and downward to loosen it, and then pull down. Just break it off if it happens. Use the pry bar to remove the shattered pieces.

- Replace the damaged board with a new one and set it on top. Get rid of the old weatherboard and use it as a guide to draw the outline of the new one. Measure the length of a gap in the wall of the structure if you so choose.

- Use a fine-toothed mitre saw blade or a handsaw to trim the length of the new weatherboard, Board B.

- Seal the ends of the brick home with silicone caulk that can withstand the elements. Use a hammer to firmly tap the new weatherboard onto the building. Board An must be slack enough so that Board B can slide under and behind it. To do so, you may need to pry it up somewhat. With a little effort, board B may be used to effortlessly elevate board A just by sliding beneath board A. The weatherboard's edge can be held in place with a woodblock while it is tapped into place. Put the A and B boards on the ground.

- Use the nail pattern of the already-installed weatherboards to secure the new one. Make sure you use nails with shanks that are at least 3 times as thick as the weatherboard's density.

- Seal the cracks using silicone caulk that can withstand the elements. Apply one thin coat of acrylic paint that will hold up in all conditions using a brush. When the first layer has dried completely, apply the second.

Repairing Damaged Wood On The Outside Of Your Home.

Weatherboard, flooring, and fences are examples of exposed wood that can be damaged or deteriorated by the weather. While painting is a great way to update the look of weathered wood, it won't hide flaws like cracks, rot, or holes. A well-applied coat of paint is a great technique to give the impression that wood has been used. In order to prevent problems from occuring again and to fully appreciate a great surface, it is crucial to thoroughly repair and infill any affected parts upon that timber's surface. At Hitch Property Constructions, we offer Melbourne weatherboard repairs services.

Needed Are The Following:

- Exterior Polyfill Lumber.

- This filling blade can be used for a variety of purposes.

- Essentially, it's a scraper.

- Sandpaper.

Instructions.

- Ensure surface surfaces are neat and dry ; eliminate any rotting wood and mend split lumber firmly prior to filling. No priming is required.

- Fill in any gaps with confidence using Polyfilla Exterior Timber and your filling blade. Scrape off any extra to conserve effort sanding. Permit a thin application of 2-3 mm to dry in two to three hours, depending on the relative humidity. In deeper tasks use during 10mm layers, enabling each layer to cure entirely previous to utilising the rest.

- You should sand it down until it is uniform in texture, then apply a coat of high-quality exterior water or gas paint, or a coat of stain and clear varnish.

- For a better finish let filler to cure, sand back and apply another super thin coat of filler. After it has dried, smooth it using fine (> 300 grit) sanding before painting or varnishing.

- Protect from moisture until painted, and for the best results, use an undercoat before painting the exterior.

Keeping Up With Repairs To The Siding Or Weatherboards.

Maintaining weatherboards is important. Wood, fibre cement, aluminium, and PVC all require different cleaning strategies due to differences in vintage, structure, & installation. Pick a board member who fits the bill. Various'systems' can be found.

Wash it every six months with a soft toothbrush and fresh water to keep it looking excellent.

"Homes constructed with weatherboard are notoriously problematic and high-maintenance. Keep them painted, and every 5–10 years, swap out the cladding. The lumber may have rotted or there may be other issues if you don't." 2008 AIA.

A Leak In The Resin.

On newly cut wood, the sap takes for anything from a year till two to fully develop. You will need to wipe the resin on a constant schedule, and after it has entirely stopped, you will want to sand the afflicted area down to the bare timber, prime with a alkyd-aluminium primer, and afterwards coat and paint it.

Rot.

If wood is not treated adequately (a minimum of H3.1—H3.2 if untreated, H4 for trundles in with the ground, and H5 for piles) or there is a continual presence of wetness (a dryness content of far more than 20 percent). The wood will need to be replaced after you've eliminated the moisture problem at its source. (Note: Is if lumbers are not handled in whatsoever way, you should consult an expert before deciding how much wood should be replaced. Recommendation right now is to swap to wood that's 600 mm beyond the recent point od damage.

Joints Being Opened.

The connectors were not lubricated as effectively as they should be because of the timber's movement (inflation and contract) or the absorbing of moisture. Scrape off the old paint, prime board surface as specified, then cover the join ends in covered boards to box with in corner.

Painting failure, which is usually caused by incorrect application to begin with (but utilising dark colours can perhaps have helped). Remove the existing coating, prime or Scrape, but then just repaint.

Cupping.

This problem can be caused by shifting lumber, using too many nails, or skipping the step of priming the backside of the boards. If you need to replace any wood, do so, and then prime / urethane coat it before painting it.

Creating Two Or More Parts.

Activated by two nails being driven into a board at the same time or by the movement of timber. Use a shim to make this split or crack wider. After applying water-resistant hardwood adhesive (PVA or resin), remove it shim from the wood and then press the parts back into their previous locations. Fasten the top and bottom pieces together using nails or pins. Use a fabric that was soaked to remove any excess adhesive. Nail it back together using a single line. Re-painting could be required.

Replacing Cracked And Broken Weatherboard.

Any of the various profiles can be used for the replacement of a damaged board with identical replacement steps. Nails are typically hammered into the studs every 4.5 to 6 inches along the lower border of each board. The leading edge is held firmly in place by the stapling of the board above. When clearing out a large space, begin at the bottom you work your way upwards.

You can employ a drill to drive the nails and through damaged board if you’re able to see them. It is impossible to utilise a punch if the nails are hidden from view. The same holds true for driving them through the undamaged board above to release the leading edge.

Lift the wood that used a short pressure bar, and if you can't see the nails, put the blade of a little straight hacksaw under it. Examine this area to detect the needles, but then cut them.

And use a but further or pocket saw in the blade in the direction opposite, detach the broken board from the cabinets. Check for squareness and make sure the joints don't connect to any other cuts.

Galvanized nails should be used to secure the new board, and installation should begin at the bottom and progress upward. New board should have sealant sprayed to the joints and any other exposed areas.

Paint after priming the surface.

If You Need To Replace Your Rotten Multiple Integrated With New Cladding, Why Not Go With Vinyl Or Pvc?

You may get vinyl cladding in a wide variety of colours and styles. A lot more essential, vinyl outlives practically every other outside surface area. Vinyl likewise declines and expands in accordance with the weather situation, it makes it longer-lasting but less exposed to break, rip, or wear down. Vinyl cladding is typically made to endure at least 30 years.

Vinyl's lengthy life also gives it the best limited outer surface area solution for your house. The vinyl weatherboards can be easily repaired by exchanging only the damaged section. What may be faster or more cheap?

There are tonnes of additional rewards for selecting vinyl cladding. As fact, the extra layer around your property and gives more fortification through into the heat and the cold.

Your vinyl, meanwhile, will look as good as new for many years with almost any effort on your part. Additionally, it delivers a cool but sleek aspect to your property that color or any treatments may not utilise long-term. Wood pole dancing, stucco, rough-cut cedar, & stone are just some of the many aesthetic options.

Vinyl soffit and fender, blinds, and window treatments all complement this for a more finished, attractive look for your home. You may also blend patterns and color for a particular aesthetic attractiveness that should set your property apart from the rest in your neighbourhood.

PVC cladding, which uses a mechanism where it pieces are fastened to one another, provides superior thermal insulation comparing to brick, concrete, or lumber. They come in a wide range of dimensions with coordinating colours and edge trims.

Just What Sorts Of Fixes Will Need To Be Made?

In normal circumstances, the only maintenance vinyl or PVC cladding should need is the occasional washing without soap and hot water, or using one of the specialised cleansers available specifically for vinyl with PVC cladding. That ought to be enough to preserve the sheathing in good shape.

Considering installing gutters on your home is a smart idea if you don't already have them because they help divert water away from the house's exterior, where it can cause mildew and mould, and keeps the vinyl from warping. Gutter installation is something to think about if your house does not already have them. Microfiber covering which have been chemically treated to inhibit the formation of mildew and mould can help mitigate this problem.

When Do You Know It's Time To Yank Out That Rotten Weatherboard?

Most homeowners will eventually dispose of the original weatherboards that were put up on their homes when they were constructed, but weatherboards that have sustained just minor damage can be restored, treated, and reused. Wooden weatherboards are sometimes overlooked in the building business, despite the fact that they can effectively serve their job for decades if cared for properly.

Identifying the timber planks that can be repaired, retained, and reused after being repurposed will require close examination. If the board appears to be sturdy and free of termite damage but has simply shifted out of place, nail it back into place. In contrast, if the board is drooping, mushy to the touch, or shows any other indicators of decomposition, you should leave the project or go for a professional. Check out Hitch Property Constructions for a huge range of weatherboard repairs Melbourne services.

Conclusion

Long and flat, weatherboards are an exterior siding option. When installing weatherboards, it is common practise to overlap them to create a more robust barrier against the elements. Made from cement sheet, they are available in a variety of profiles to complement both traditional and contemporary architecture. Although synthetic weatherboards are more resistant to wear and tear than their natural counterparts, they are still easily damaged.

Content Summary

- Weatherboards are often made from pine and are pre-primed, meaning that a single coat of primer has been put to both sides to preserve them from the elements.

- My own opinion is also that weatherboards convey an air of refinement and may be found in nearly every era of architecture in Australia.

- The most recent improvement in weatherboard technology is the treated wood variety.

- Weatherboards can be fabricated from cement sheet and come in a range of profiles to suit both classic and modern home designs.

- Weatherboards are a type of exterior siding that are long and flat.

- Homes can be made more secure and attractive with the use of weatherboards.

- The weatherboards on a building are overlapped during installation to form a strong defence against the elements.

- Get yourself acquainted with the insulation boards you'll be dealing with, including the board you'll be replacing, the board above it, and the board below it.

- Try jamming the end of a crowbar between planks A and B. Two nails, one at the top and a second at the bottom, are used at each stud throughout the length to secure the weatherboards.

- To remove the nails, strike them with a claw hammer.

FAQs About Weatherboard

At some point in the life cycle of your weatherboard home, there will be a need to replace a weatherboard that exhibits timber rot. Weatherboards fail for many reasons some of which include; poor installation, incorrect undercoat and top coat painting and the milling of young timber.

Weatherboards are made from timber or reconstituted hardwood that can be painted or stained to choice, or they can be made from vinyl. Timber weatherboards or weatherboards that contain timber use timber that is from sustainable sources.

Weatherboard is generally considered “pretty tough” but not as tough as bricks and is prone to some issues that must be considered when buying a weatherboard house.

What is Hardwood Weatherboard? Weatherboards are reconstituted timber and hardwood that are stained or painted to fit your preference. In Australia, hardwood weatherboard can be constructed from cypress pine, Tasmanian oak, gum, and mahogany tree.

It's possible to brick a weatherboard house, but it can be a costly renovation. Brick does have many advantages as a cladding material for a weatherboard home. To convert a weatherboard home, a contractor will develop a plan that might involve redoing plumbing and windows to properly brick the house.