Do you want to remodel your current house or construct a new one? Waterproof plastering is a must if you want your walls to survive a long time without being damaged by dampness.

What, though, is the secret ingredient in watertight plaster? In this piece, I'll break down the fundamentals of this specialised plastering method, so you can give your walls a surface that will last and repel water.

Using a cementitious waterproofing compound is essential for watertight plastering. This material combines cement, polymers, and other additives to repel water.

Including these components makes the plaster extremely water resistant, protecting the walls from water damage and keeping them in good shape.

The purpose of the cementitious waterproofing compound is to form a barrier that prevents water from penetrating the underlying surfaces.

But how exactly does this stuff function? What makes it different from other plastering methods?

We'll go deeper into the properties of the cementitious waterproofing compound and the methods used to apply it to comprehend the science underlying waterproof plastering and investigate its many advantages.

This article will give you, the homeowner or professional builder, the information you need to choose the best waterproof plastering for your next project.

What Is Waterproof Plastering?

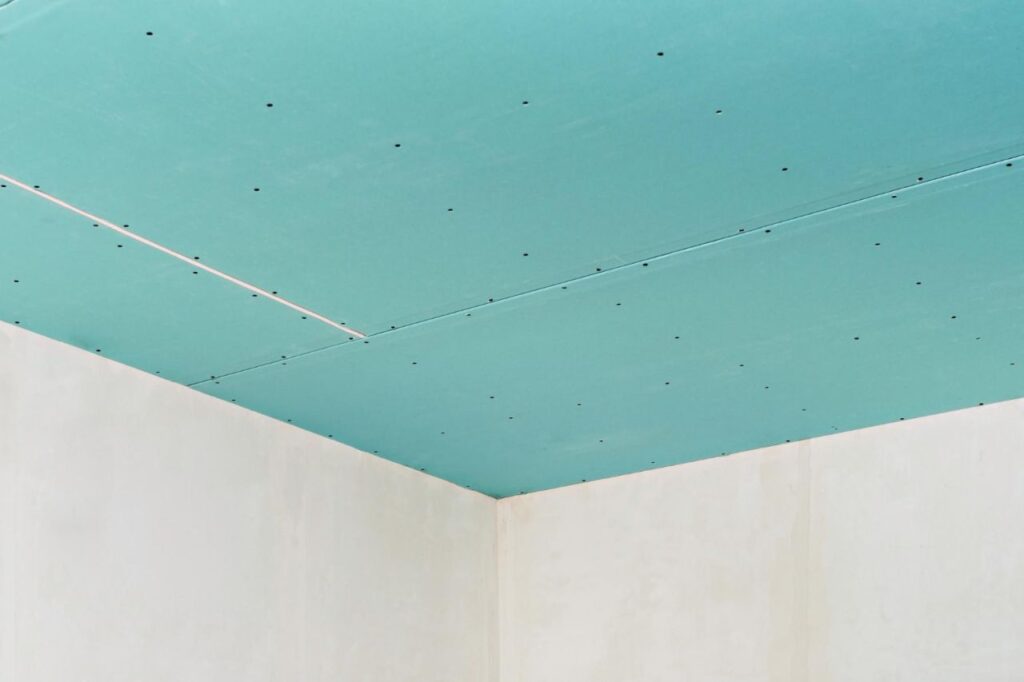

Waterproof plastering, also known as waterproof rendering, is a method used in construction to prevent water from penetrating the surface of a building. Plastering or rendering with a substance specifically formulated to resist water is what this refers to.

Waterproof plastering normally begins with surface preparation, which entails cleaning and removing any debris from the area to be covered. Waterproofing is accomplished by incorporating an additive into the plaster or rendering mixture after preparing the surface.

This chemical increases the material's water resistance and blocks moisture from penetrating it.

The surface is subsequently coated with the waterproof plaster or rendering mixture using a trowel or a sprayer, among other methods. Plaster is applied in layers until the appropriate thickness is reached and a uniform sheen is achieved.

Plaster must be adequately compressed and adhered to the underlying substrate during application to produce a watertight seal.

Both water- and moisture-resistant plastering is widely utilised in damp environments, including basements, baths, swimming pools, and exterior walls. The resistance to water, moisture, and mould growth it gives makes the building stronger and more long-lasting.

Waterproof plastering is distinct from damp proofing, primarily concerned with stopping water from seeping up through the foundation. On the other hand, waterproofing involves constructing a barrier to keep water out.

It is advised to get the advice of experts in the waterproofing field before beginning any waterproof plastering project. Based on the project's needs, they may advise you on the best materials and how to use those materials.

What Are The Best Waterproof Materials?

Have you ever wondered what makes certain materials impervious to water? Whether you're looking for a raincoat that will keep you dry in a downpour or a reliable roofing material for your home, understanding the best waterproof materials is crucial.

This article will explore the top contenders in waterproofing, uncovering their unique properties and applications.

When it comes to waterproof materials, several options excel in different scenarios.

For instance, Gore-Tex, a breathable fabric, has revolutionized outdoor apparel by providing water resistance and breathability. PVC, known for its durability and versatility, is commonly used in waterproofing applications such as plumbing pipes and rain gutters.

And let's remember silicone, a flexible and long-lasting material used to seal and protect surfaces. This blog post will reveal these materials' strengths and limitations. Not to worry because we have compiled a list of the top waterproof supplies currently available:

Rubber

Rubber is frequently used because it is watertight. It's used to prevent water from penetrating items like gloves and boots. Prefabricated ancillary dwelling units also make use of rubber.

It keeps the structure intact and makes the area watertight. Rubber is a common staple in the construction of wooden garden buildings.

Polyvinyl Chloride (PVC)

PVC, or polyvinyl chloride, is a synthetic, waterproof material used for piping and other plumbing applications. PVC has a long lifespan and can serve many purposes. Tents and raincoats made from them are also common.

Natural Materials

Beeswax, oiled leather, and waxed canvas are eco-friendly solutions that may make walls and roofs watertight. They're great for indoor use because of their inherent water resistance.

Silicone

Sealing materials like tents and waterproof coats frequently employ silicone. Due to its high water resistance, it is frequently used in shed construction.

Bituminous Membrane Waterproofing

Waterproofing solutions using a bituminous membrane are ideal for 'flat roofs' or roofs with a modest gradient. This is typical of art deco and ultra-modern architecture. It has been shown to be effective in the past when applied appropriately.

The oldest method is torching bitumen onto a membrane. Self-adhering bitumen and membrane is the latest innovation. The thickness of the membrane cloth itself ranges from 2mm to 4mm.

These fabrics have a 150% elongation potential. The membrane acts as a failsafe if the bitumen develops even the tiniest cracks due to weather or other external factors.

Some seasons, with extreme heat and cold, cause significant expansion and contraction of a roof. Using a bituminous barrier to keep water out works well when this occurs.

When renovating with bitumen and membrane, remember that turning on the torch will require many hours of loud blow torching. While this would be acceptable at home, it certainly would have gone over poorly with the visitors to the hotel.

Bituminous Coating Waterproofing

A bituminous coating's exceptional waterproofing and protective covering properties make it ideal for use on concrete foundations. This process is also known as asphalt coating.

The brittleness it develops when exposed to sunshine makes it unsuitable for outdoor use. Add reflective elements or a flexible material like polyurethane to the mix to prevent this.

Cementitious Waterproofing

The components of cementitious waterproofing are simple to combine and spread. This approach is typically employed in moist indoor environments, such as lavatories, restrooms, and kitchens.

Liquid Waterproofing Membrane

A membrane and a very thin layer of primer and top coating are the components of liquid waterproofing. Use a shovel, roller, or spray to apply. With its wide variety of temperatures, the shower is an ideal environment for the liquid waterproofing membrane's greater adaptability. Depending on the polymer, longevity can vary.

Using the best products, you can extend the life of your topcoat by as much as 280%. Cementitious water resistance is less flexible and stiffer.

What Advantages Do Waterproof Materials Offer?

The versatility and usefulness of waterproof materials make them a great option for various uses. Some of the most frequently cited advantages of waterproofing a building or other structure are as follows:

Protection

Roofs and buildings that are made from waterproof materials are less likely to suffer damage from storms, winds, and extreme temperatures. Waterproof materials prevent the infiltration of harsh weather, maintaining a comfortable indoor climate.

Durability

The most reliable waterproof materials are also quite tough. Because of their durability, they are a popular choice for strengthening the framework of wooden garden sheds.

Comfort

Some waterproof materials are also absorbent, meeting the local populace's needs for a pleasant living environment. Waterproofing materials help maintain a comfortable indoor temperature, even when the weather outside is hot and muggy. Also, even in the dead of winter, the interior is toasty.

Versatility

There are several kinds of waterproof materials, and they all serve different purposes. Rubber and membrane are two examples of waterproof materials with a specific niche in the roofing industry. Other watertight materials, like PVC, are typically reserved for plumbing and structural applications. In sum, they have several potential applications.

Eco-Friendly

The vast majority of waterproofing products are eco-friendly and non-toxic. In the long run, using these supplies lessens the harmful effects on the environment.

How To Know If You Have A Waterproofing Problem?

Buildings' structural integrity and protection from water damage are both greatly aided by waterproofing. Leaks, mould growth, and even structural damage are all problems that could arise if waterproofing systems deteriorate over time.

Early detection of waterproofing issues is crucial for avoiding extensive damage and expensive repairs. Indicators that can be used to tell if there is a problem with waterproofing are discussed in this article.

Water Leaks

Water leaks are a telltale symptom of an issue with the waterproofing.

Investigate any wet spots, pooling water, or water stains on the walls, ceilings, or floors. The roof, the basement, the bathroom, and the regions around the windows and doors are all potential sources of water infiltration. Water damage can be mitigated if you act quickly after discovering its presence.

Mould and Mildew

Mould and mildew flourish in damp environments. Look for mould or mildew on the walls, ceiling, or other surfaces, and smell for musty or mouldy odours.

Mould can cause structural damage to a building and even make people sick. Detecting the origin of the dampness and fixing the waterproofing issue are priorities if mould appears.

Deteriorating Walls or Floors

There can be a lot of trouble if water gets inside a building. Examine the walls for flaking paint, bubbling wallpaper, or eroding plaster.

Look for efflorescence in basements, a white powdery deposit on concrete surfaces that indicates water seepage.

Floors should also be checked for cracks, buckling, or warping, which may be evidence of water damage.

High Humidity

Inadequate waterproofing can lead to an overabundance of moisture in the air. Humidity levels in a home or building should be checked regularly. High humidity, condensation on windows, or an overall moist atmosphere may indicate faulty waterproofing. In addition to making you miserable, excessive humidity encourages mould growth and endangers the stability of your home's construction.

Pest Infestation

Problems with waterproofing can make the home hospitable to insects, including cockroaches, termites, and ants.

These bugs thrive in moist environments and can exacerbate the harm done to weakened structures. Increased pest activity is a warning sign that you must look into the possibility of water entry and fix any waterproofing problems immediately.

Rising Energy Bills

The efficiency of your home's energy system may decrease due to water penetration.

Waterproofing issues may be to blame for rising energy costs if there is no other explanation for the increase. Water penetration can compromise insulation materials, resulting in heat or cool air loss and an increase in energy consumption.

Exterior Warning Signs

Make sure you check the outside of your house as well. Check for crumbling mortar, missing or broken tiles, and deteriorating caulking around the house's openings. These outside warning signals may indicate a need for further investigation into waterproofing issues.

Conclusion

Plastering a structure to make it waterproof is a common practise in the construction industry. After the surface is ready, an additive is incorporated into the plaster or rendering mixture to obtain the desired effect.

Plaster is put in thin layers until the desired thickness is reached and a smooth, even finish is produced.

It finds widespread application in moist areas like cellars, bathrooms, swimming pools, and external walls. The protection it provides against water, moisture, and mould growth helps to make the structure more robust and durable.

Plastering that is both waterproof and damp proof entails the installation of a barrier to prevent water from penetrating the surface. If you want to make sure your waterproof plastering project turns out well, consulting with professionals is a must.

Gore-Tex, polyvinyl chloride, natural materials, silicone, and bituminous membrane are all great options for waterproofing.

Gore-Tex is a waterproof, windproof, and breathable material. Pipes and other plumbing fixtures often make use of polyvinyl chloride (PVC), a synthetic material that is both waterproof and durable.

Beeswax, oiled leather, and waxed canvas are all examples of natural materials. Silicone is a sealant and protective coating that is both versatile and long-lasting.

Waterproofing with a bituminous membrane works well on low-slope or flat roofs. Torching bitumen onto a membrane is the earliest way of waterproofing a structure.

The newest development is a self-adhering bitumen and membrane that has the ability to stretch by 150%.

Waterproofing a concrete slab with a bituminous coating is the best option, whereas cementitious coatings are more common in humid interior spaces. When applied over a topcoat, liquid waterproofing membrane can increase its durability by as much as 280%. Waterproofing a structure can improve its safety, longevity, and occupant satisfaction.

Materials used for waterproofing have many benefits, including their ability to keep the interior of a building at a reasonable temperature, their adaptability, and their low environmental impact. Finding leaks in the waterproofing before they cause major problems or expensive repairs is crucial.

Leaks, fungus, and structural degradation are all warning signs.

Mould and mildew can create expensive structural damage and health problems, and water leaks are a telltale sign of trouble.

If mould starts to grow, it's time to investigate the source of moisture and address any waterproofing problems.

Look for signs of peeling paint, bubbling wallpaper, eroding plaster, efflorescence, cracks, buckling, or warping; excessive moisture; pest infestation; soaring utility costs; missing or broken tiles; and deteriorating caulking around windows and doors. If any of these red flags appear, it may be time to look into the waterproofing.

Content Summary

- Waterproof plastering is essential for long-lasting walls and protection against dampness.

- The secret ingredient in watertight plaster is a cementitious waterproofing compound.

- Cement, polymers, and additives are combined to make the plaster highly water-resistant.

- The compound forms a barrier that prevents water from penetrating the walls.

- Waterproof plastering is different from damp proofing as it focuses on keeping water out.

- Surface preparation is crucial before applying waterproof plaster or rendering.

- Additives are incorporated into the plaster mixture to increase water resistance.

- The plaster is applied in layers until the desired thickness and sheen are achieved.

- Waterproof plastering is widely used in damp environments like basements and bathrooms.

- It strengthens buildings and protects against water, moisture, and mould growth.

- Expert advice is recommended for choosing the best materials and methods for waterproof plastering.

- Understanding the best waterproof materials is important for various applications.

- Gore-Tex is a breathable fabric that revolutionised outdoor apparel with its water resistance.

- PVC is a durable and versatile material used in plumbing pipes and rain gutters.

- Silicone is a flexible and long-lasting material commonly used for sealing and protection.

- Rubber is used to make items like gloves, boots, and wooden garden buildings watertight.

- Natural materials like beeswax and oiled leather offer eco-friendly waterproofing solutions.

- Bituminous membrane waterproofing is effective for flat roofs and modern architecture.

- Bituminous coating is suitable for concrete foundations but not for outdoor use.

- Cementitious waterproofing is commonly used in moist indoor environments like bathrooms and kitchens.

- The liquid waterproofing membrane is applied with primer and top coating, offering adaptability.

- Waterproof materials provide protection, durability, and comfort to buildings.

- They offer versatility and have eco-friendly and non-toxic properties.

- Detecting waterproofing problems early is crucial to avoid extensive damage and costly repairs.

- Water leaks, mould and mildew, and deteriorating walls or floors indicate waterproofing issues.

- High humidity and pest infestation can also be signs of faulty waterproofing.

- Rising energy bills may be attributed to compromised insulation due to water penetration.

- Exterior warning signs like crumbling mortar and deteriorating caulking should be investigated.

- Waterproof materials contribute to the structural integrity and longevity of buildings.

- Regular maintenance and proper waterproofing help protect against water damage.

FAQs About Waterproof Plastering

Yes, waterproof plastering material can be used to repair areas that have been damaged by water. It helps to restore the integrity of the surface and provide waterproofing to prevent further damage.

The drying time of waterproof plastering material can vary depending on factors such as temperature, humidity, and the specific product used. Typically, it may take anywhere from 24 to 72 hours for the material to dry and cure completely. It is important to follow the manufacturer's instructions for the recommended drying time.

Yes, once the waterproof plastering material has fully cured and dried, it can be painted over with compatible paints or coatings. It is recommended to use waterproof or moisture-resistant paints to maintain the waterproofing properties of the plastering material.

Yes, waterproof plastering material can be used on roofs as part of the waterproofing system. It provides an additional layer of protection against water penetration, helping to prevent leaks and moisture damage.

The application process for waterproof plastering material may vary depending on the specific material used. However, in general, it involves the following steps:

- Surface preparation: The surface to be plastered should be clean, dry, and free from any loose particles or contaminants.

- Mixing: The waterproofing material is mixed according to the manufacturer's instructions, ensuring a consistent and workable consistency.

- Application: The material is applied using a trowel, brush, or sprayer, depending on the type of material and the surface area to be covered. Multiple coats may be required for optimal waterproofing.

- Curing and drying: The plastering material needs time to cure and dry completely. This process allows the material to form a strong and waterproof barrier.